Our first post should probably be about the media coverage and influx of interest and enquiries from this month’s launch of our pilot with the City of Greater Geelong’s Green Waste Processing Facility, we’re instead running ahead with another exciting announcement!

New Life for Resource Recovery Centre Harvested Li-Ion Batteries

We have received a $46,200 Circular Economy Markets Fund: Materials grant from the Victorian Government through Sustainability Victoria for our project New Life for Resource Recovery Centre Harvested Lithium Ion Batteries.

Our Design Ethos

Our design ethos even before selling a single Rhino device was a commitment to designing something with the least environmental impact possible.

This covers materials choice and designing for longevity:

✅ Fully recyclable all-metal enclosure

✅ Gorgeous ‘witches brew’ recycled LDPE plastic inside

✅ Gaskets instead of glue for easy user access

✅ Connectors instead of solder making part replacement easy

✅ A commitment to sell replacement parts

✅ Embracing the right to repair movement with a label that invites people in

✅ A battery chemistry that’s not just recyclable but actually gets recycled <- This is important!

Battery recycling rates in Australia for different chemistries

Lead acid batteries are heavy, toxic if not handled properly, and have a low energy density. You’d think they’re a pretty average choice, but actually we think they’re great for two reasons:

- They don’t mind being hot in the sun

- There is an industry built around recycling over 98% of them in Australia

Li-ion batteries are in most ways a far better battery, that’s why they power more and more of our devices.

They too are also fully ‘recyclable’. Except only 10 percent actually get recycled in Australia. As we’ve learned in recent years with the Australian recycling crisis, there can be a chasm between something being recyclable and a country actually being able to meaningfully process recyclable waste.

I believe Australia will build the capacity to properly handle Li-ion battery recycling but it will take time. In the meantime we want to contribute to closing the chasm. That’s what this grant is going to help us with.

Safely reusing 18650 Li-ion cells

We’re looking for a scalable way to reuse some of the millions of ‘dead’ Li-ion batteries in our waste stream that aren’t even close to dead.

The challenges are economic, regulatory and technical.

Let’s explore what I mean here looking at a common laptop battery I opened up.

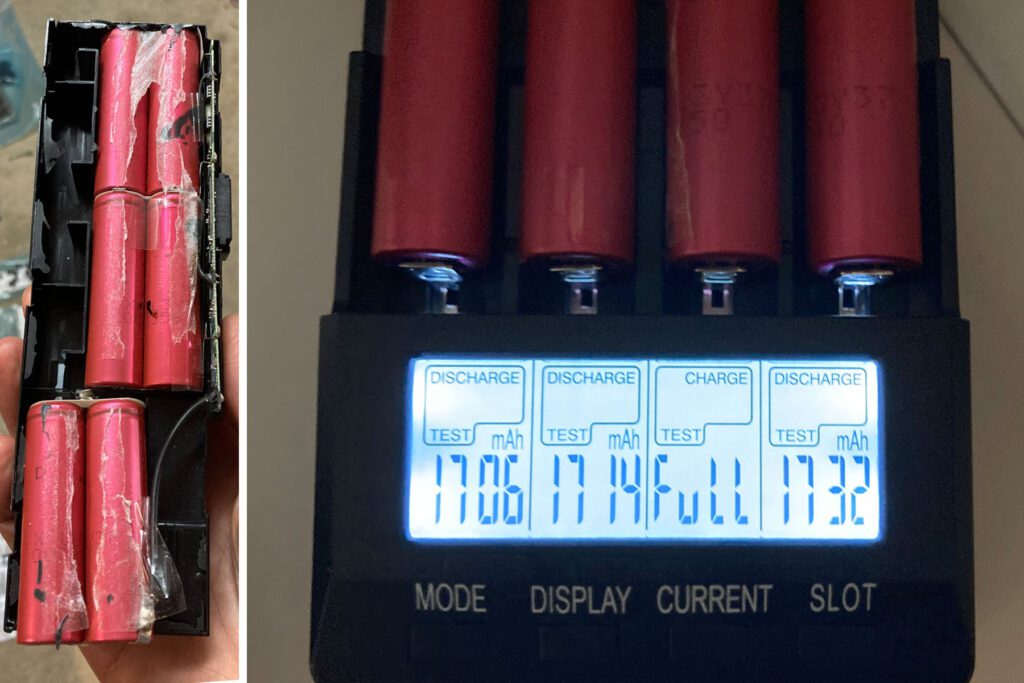

On the left what you can see is that there’s actually a number of smaller standard 18650 cells chained together. Wedged in on the right hand side of the laptop battery you might be able to see a thin circuit board, that’s the Battery Management System (BMS) that makes all those cells appear as a single battery to the laptop. Cordless power tools and many other Li-ion powered devices work the same way.

For all their advantages, Li-ion cells can be pretty picky about how they’re charged and discharged. If done incorrectly they can be a risk of catching fire and/or exploding.

The BMS is the piece of circuitry that ensures the cells are kept within their limits. If it detects something is amiss it will shut the pack down.

To keep the cost and size of the overall battery down, many BMS’s rely on all the internal cells being very close in capacity so the cells don’t have to be managed individually. The only problem is what often happens is one cell gives up early and the BMS decides the whole battery pack can’t be used safely.

Extracting the cells in our example pack and checking them individually shows that they still have useful life left in them. You can see this on the right hand side of the above photo.

We’re aiming to demonstrate how a BMS that’s specially designed to accept second hand 18650 batteries with mixed capacities could work.

The challenges

There are many people online extracting and reusing 18650 Li-ion cells however these cells aren’t always being strung together safely.

When they are strung together safely, it’s a labour intensive process. You have to charge them individually, deplete them to find out their capacity, and mark them so they can be re-matched with other used batteries that have the same capacity.

Then to do this on a commercial scale you start to hit up against regulatory limitations. When we completed the compliance on the RM1 we had to choose a single battery and speak to the manufacturer to get their safety test data to show it complies with our laws.

If someone tried to produce a product with a mix of reused batteries, how would that make it through regulatory testing to ensure it complies with the relevant laws?

Those challenges are the areas we will be exploring.

The opportunity

The opportunity for delaying the disposal of Li-ion batteries is massive.

According to the CSIRO research lithium-ion battery waste is growing by 20 per cent a year and could exceed 100,000 tonnes by 2036.

If not dealt with properly, lithium-ion batteries pose environmental, health and safety concerns.

We’re proud to support Victoria’s transition to a circular economy through our project New Life for Resource Recovery Centre Harvested Lithium Ion Batteries.